The Role of HIL Testing in a Resilient Energy Future

Published by Kristian Ilasko,

Digital Content Coordinator

Energy Global,

As power systems have been becoming more complex and decentralised, the risk of blackouts grows, often triggered by cascading failures or poor co-ordination among grid controllers and protection components. Traditional testing methods no longer meet the resilience requirements of today’s evolving grid.

Energy Global spoke with Renzo Fabian, Head of the Flex Power Grid Lab at KEMA Labs, about how Hardware-in-the-Loop (HIL) testing is helping utilities and manufacturers validate protection systems and prepare for the future.

How is grid evolving, and what challenges does this create for testing?

The integration of renewables and distributed generation has made the grid more dynamic. Unconventional operational conditions require innovative approaches not only during design, but even during testing. HIL, which places real hardware in closed loop with a simulated grid, has become essential. It allows testing not just individual devices, but also of how multiple components interact with one another and with the wider system.

By replicating realistic and dynamic conditions, HIL enables thorough evaluation of device behaviour, interoperability, and response to disturbances. This reduces risks and provides valuable insights before technologies are deployed into the field.

What are the limits of traditional testing methods?

Traditional approaches often focus on single components under static scenarios. With fluctuating power flows, lower inertia and bi-directional exchanges, it is crucial to test how devices interact across a wide range of conditions. Recent large scale blackouts have underscored the risks of overlooking interoperability and system-level behaviour.

How does HIL testing address these challenges?

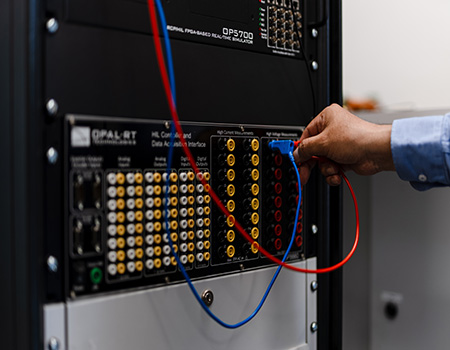

HIL involves connecting devices under test to a real-time simulator that models the electrical grid. The simulator produces voltage and current signals that are applied to the device creating a closed feedback loop. HIL testing can be divided into two main categories. Control HIL (CHIL) focuses on testing controllers, protection relays and automation systems, sometimes requiring voltage and/or current amplifiers to properly interface with these real devices. Power HIL (PHIL), tests power-handling equipment, such as converters, exchanging actual electrical power with the simulated grid. PHIL always requires amplifiers. These methods allow engineers to model diverse HIL configurations and scenarios evaluating both individual performance and collective behaviour.

What is the specific value of HIL for protection relays?

Unlike conventional testing that uses pre-recorded signals, HIL creates a closed-loop environment where the relay’s actions influence the simulated grid and vice versa. This enables holistic testing of coordination, among multiple relays under realistic grid conditions. As a result, engineers can validate fault detection, protection logic, and relay co-ordination before deployment.

How do renewables impact protection, and how can HIL help?

Most existing protection principles were developed decades ago. Grid-connected converters have introduced fundamentally different fault responses; they supply limited fault currents and distinct sequence components. Traditional protection schemes and relay settings are no longer sufficient. HIL enables testing of converter-dominated grids under varied fault conditions. This allows the optimisation of relay settings, validation of protection strategies, and reduction of misoperation risks in renewable-heavy power systems.

Can HIL improve interoperability across vendors?

Yes. Real grids combine equipment from multiple manufacturers that must operate in harmony. HIL makes it possible to test interoperability in realistic conditions identifying mismatches, communication issues, or coordination gaps before deployment. This ensures smoother integration and greater system stability.

What is KEMA Labs’ approach to HIL testing?

KEMA Labs operates real-time simulation platforms and calibrated amplifiers to perfogreater system PHIL testing. The lab invests in next-generation solutions, such as testing traveling-wave protection relays requiring high-bandwidth amplifiers not yet available on the market. For PHIL applications involving relevant apparatuses, megawatt-level amplifiers are essential, and KEMA Labs is actively developing this capability. Our laboratory also aligns its methods with standards like IEEE P2004 while exploring hybrid CHIL-PHIL setups that reduce delays and expand bandwidth.

What are the benefits for customers working with KEMA Labs?

As an independent lab with decades of sector experience, KEMA Labs provides impartial, technically rigorous validation that manufacturer or in-house labs cannot always guarantee. Its results are trusted by utilities, regulators, and stakeholders worldwide. Our advanced HIL facilities, among the few of their kind globally, allow us to test complex systems under realistic grid conditions, identifying issues and optimising performance before deployment. This combination of independence, expertise, and unique capabilities helps clients reduce risk, avoid costly failures, and accelerate project approval.

For more information please visit KEMA Labs - CESI Group.

Read the article online at: https://www.energyglobal.com/special-reports/01092025/the-role-of-hil-testing-in-a-resilient-energy-future/

You might also like

Cadeler signs preferred supplier agreement for foundation installation in 2028

Cadeler has signed a preferred supplier agreement with an undisclosed client for the transportation and installation of monopiles and transition pieces at a large offshore wind farm located in European waters.